Electric Power Steering (EPS)

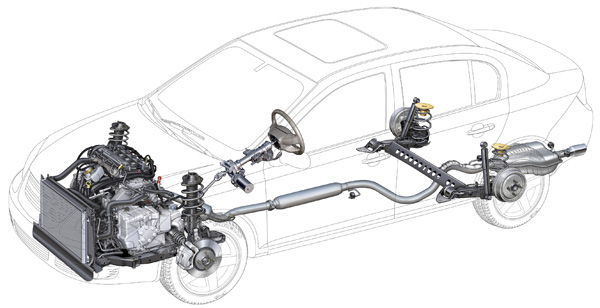

If you were to look at the underside of a 2005-2010 Chevy Cobalt or Pontiac G5, the recipe doesn’t look that much different that a 1995-2004 Chevrolet Cavalier or Pontiac Sunfire. The basic ingredients of a strut front suspension and loaded beam axle rear suspension are still there. But, GM introduced several new ingredients that can change how this vehicle is aligned.

If you were to look at the underside of a 2005-2010 Chevy Cobalt or Pontiac G5, the recipe doesn’t look that much different that a 1995-2004 Chevrolet Cavalier or Pontiac Sunfire. The basic ingredients of a strut front suspension and loaded beam axle rear suspension are still there. But, GM introduced several new ingredients that can change how this vehicle is aligned.

The greatest difference in the 2005 Chevy Cobalt can’t be seen from under the car. It is the electric power steering (EPS). Knowing the basics of this system can save you problems before the vehicle is pulled into the alignment bay.

EPS eliminates the power steering pump, which can use as much as 8 to 10 horsepower under load. This improves fuel economy while also eliminating the weight and bulk of the power steering pump and hoses. Getting rid of the hydraulics also does away with leaks and the need to check the power steering fluid.

When the driver turns the wheel, a steering sensor detects the position and rate of rotation of the steering wheel. This information, along with input from a steering torque sensor mounted in the steering shaft, is fed to the power steering control module. Other inputs, such as vehicle speed and inputs from the traction control or stability control systems, are factored in to determine how much steering assist is required. The control module then commands the motor to rotate a certain amount, and a sensor on the motor provides feedback to the control module so it can monitor the motor’s position.

If a sensor or other component in the EPS system fails, the self-diagnostics should detect the fault, set a code and disable power-assist. A warning light will illuminate to alert the driver, and the driver will notice a significant increase in steering effort when turning the vehicle.

The Cobalt’s EPS system has four modes of operation. By understanding the four modes, you can make a diagnosis in less time.

The Cobalt’s EPS system has four modes of operation. By understanding the four modes, you can make a diagnosis in less time.

• Normal mode: Left and right assist is provided in response to inputs and vehicle speed.

• Return mode: Used to assist steering return after completing a turn. Feedback from the steering position sensor prevents the EPS system from “overshooting” the center position. If the steering position sensor is faulty, it can cause “on center” problems when the toe is set.

• Damper control mode: Used to improve road feel and dampen kickback, this mode typically kicks in at higher vehicle speeds. If the caster angle is too far out of specification, the damper mode can over or under compensate.

• Protection mode: Protects electrical components from thermal damage and excessive current flow if the steering is held all the way to one side in the lock position too long.

The steering wheel position sensor determines the “on center” position. This is used to keep return assist from going over center once a turn is completed. The GM unit is a 5-volt dual analog triangle signal device with a valid signal voltage range of 0 to 5 volts. The sensors’ signal 1 and signal 2 voltage values will increase and decrease within 2.5- to 2.8-volts of each other as the steering wheel is turned. This information can be very useful during diagnosis.

In GM EPS systems, the Power Steering Control Module (PSCM) must be set up with the correct “steering tuning,” which are different in relation to the vehicles powertrain configuration, sedan, coupe, tire and wheel size, etc. This may require a scan tool with flash capabilities.

If you are trying to diagnosis EPS or a suspension making noise, there is a simple trick. GM has a technical service bulletin (07-02-35-004 Feb. 02, 2007) out on a noise problem with EPS steering on the Cobalt, Chevy HHR and Pontiac G5. The bulletin describes a steering column rattle or knocking noise that may be heard or felt at low speeds (5 to 15 mph).

The noise is most noticeable when making a slow turn on a loose or rough surface. The EPS system can be temporarily disabled by removing the 60-amp EPS fuse in the underhood fuse block.

If the rattle persists, it is due to backlash within the steering column (assist motor gear mechanism).

Replace the 60 amp EPS fuse and test drive again. If the steering column is identified as the source of the rattle/knocking noise, the steering column needs to be replaced.

Front Camber Adjustment

If this is not the vehicle’s first alignment, loosen both strut-to-knuckle nuts just enough to allow for movement. The factory recommended procedure is to elongate the lower strut mounting holes. If the strut has not been modified previously, it is more profitable to install aftermarket cam bolts.

Front Caster

The front caster is not adjustable. If the front caster angle is not within specifications, inspect for suspension support misalignment or front suspension damage. Replace any damaged suspension components as necessary. The inboard rear bushing is susceptible to wear and damage that could produce positive caster. It will also make a clunking noise on acceleration and braking.

Front Toe

Ensure that the steering wheel is set in a straight-ahead position. Loosen the tie rod jam nut. Adjust the toe to specification by turning the adjuster. Tighten the tie rod jam nut to 68 Nm (50 ft. lbs.) when the adjustment is completed.

Rear Toe and Camber

Rear Toe and Camber

The rear suspension is a loaded beam axle. While it is difficult to damage this large part, it can be prone to wear and tear on the bushings, swaybar mounts and spring insulators.

The rear suspension angles can be adjusted with the installation of a shim that is placed between the rear hub and axle mounting plate. A shim should be able to change toe or camber 1 to 1.5 degrees. If a shim is required, make sure that one is not already installed on the vehicle. If one is present, remove the old shim and measure the base line angles.

It has been reported that on some rear disc brake vehicles, the introduction of a shim may cause the caliper to bind or the rotor to strike the caliper bracket.

TPMS Sensor Matching

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off.

3. Press and hold the keyless entry fob transmitter’s LOCK and UNLOCK buttons, at the same time, for about five seconds to start the TPMS learn mode. The horn sounds twice indicating the TPMS receiver is ready and in learn mode.

4. Starting with the left front tire, activate the sensor by holding the TPMS tool aimed upward against the tire sidewall close to the wheel rim at the valve stem location. Press and release the activate button and wait for a horn chirp.

5. Once the horn chirp has sounded, the sensor information is learned and the turn signal in the next location to be learned will illuminate. On most models, the driver-side front turn signal also comes on to indicate that corner’s sensor is ready to be learned. Once the learn mode has been enabled, each of the sensors unique identification codes can be learned.

6. When a sensor ID has been learned, the module sends a serial data message to the BCM to sound a horn chirp. This verifies the sensor has transmitted its ID and has received and learned it. The module must learn the sensor IDs in the proper sequence to determine sensor’s location. The first learned ID is assigned to the left front location, the second to right front, the third to right rear and the fourth to left rear. On most models, the turn signals will individually illuminate indicating which location is to be learned in the proper sequence.

Relearn Tips

• It is best to perform the TPMS relearn procedure away from the shop in the parking lot.

• Aim at the sidewall below the valve stem, and not at the stem.

• If you cannot get a sensor to initialize, try pushing the vehicle forward a foot or two. The signals can be blocked by components like rotors, calipers and knuckles. By repositioning the sensor, it may unblock the sensor.