Winter is when the Anti-Lock Brakes (ABS) Hydraulic Control Unit (HCU) has to do the most work to make sure the tires have traction during braking, acceleration and stability corrections (ESC, DSC and ESP). When the ABS HCU activates, the pulsing of pressure can create a hydraulic jackhammer. If a line is weak due to internal or external corrosion, the line will rupture and leak.

Rock salt and deicing brines can corrode brake lines. Automakers have tried galvanization, polymer coatings and physical barriers to stop this corrosion, but these surfaces can’t prevent age and the pecking of road debris from causing corrosion.

A hydraulic brake system is only as strong as its weakest connection. Splicing together corroded line does not work in most cases, and replacing just the leaking section will result in a comeback. The best practice is to replace the hard line from the wheel well with an undamaged line. On vehicles with coated line, you must find the area where the coating is still intact.

Another factor influencing brake line replacement is how modern cars are manufactured. In most cases, the brake lines are installed on the unibody, and the subframes for the suspension are fastened to mounting points. Most of these lines are one piece and will go from the HCU or subframe connector to the caliper. Installing a pre-bent line might be cost prohibitive for the customer because major disassembly is required. One option is to use tubing that can be formed in place. Or, pre-bent tubing can be cut into sections so it can be maneuvered into place without having to remove the subframe. The placement of brake lines is not coincidental.

With ABS-equipped brakes, never take a flare for granted. To seal brake lines against 2,000 psi takes some geometry. The male and female surfaces of the fitting are three to five degrees different between the sealing surfaces. In some cases, the flare is designed to crush or compress onto the surface to form a seal, and the tolerances can stack up quickly against you. An off-center cut combined with a poorly clamped line may look fine to the naked eye, but the connection may leak when it is compressed by the fitting.

With ABS-equipped brakes, never take a flare for granted. To seal brake lines against 2,000 psi takes some geometry. The male and female surfaces of the fitting are three to five degrees different between the sealing surfaces. In some cases, the flare is designed to crush or compress onto the surface to form a seal, and the tolerances can stack up quickly against you. An off-center cut combined with a poorly clamped line may look fine to the naked eye, but the connection may leak when it is compressed by the fitting.

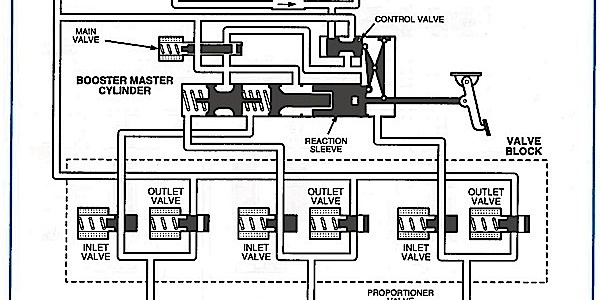

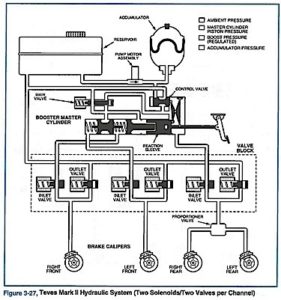

If you install new brake lines on a modern ABS-equipped vehicle, you will need a scan tool to bleed the brakes. Air bubbles in the system can occur in the modulator body if the system has lost all its brake fluid. Removing these bubbles may require the use of a scan tool to open up the isolation and dump valves in the modulator.