There are two critical measurements when installing a modern hub unit or cartridge bearing: torque and runout in the flange. Ignoring these critical numbers to save time will only lead to more comebacks and angry customers.

Torque

Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating while in operation. The torque specification for this center nut is critical to the performance and longevity of the hub.

It is nearly impossible to give a general torque specification for a locking nut. There can be significant differences depending on bearing type and housing. Always check the service information for the correct procedure. Overtightening bearings is a common error that can lead to premature failure. Tapered roller bearings on the front of RWD vehicles are never preloaded.

Many vehicles require the wheels to be on the ground for final torquing to OEM specifications. This assures the proper mating of the split inner rings of the bearing needed to achieve the proper internal clearance. For specific mounting instructions, refer to the vehicle manufacturer’s service manual for that model.

While it may appear to be easier to use an impact wrench to install or remove a locking nut, it is not recommended. OEM and bearing manufacturers always recommend using a torque wrench for installation.

During removal, an impact wrench can damage the axle nut threads and shock the CV joints. It can also create a false sense of security when adjusting a nut or bolt, which may be under- or over-torqued. This can leave a hub assembly susceptible to failure. Also, in almost all cases, use a new axle nut. Some axle nuts are designed to be used only once. Some replacement hubs come with a new nut in the box. On most modern applications, a new nut must always be used when installing a hub. Reuse of the old nut could potentially cause the nut to loosen during vehicle operation.

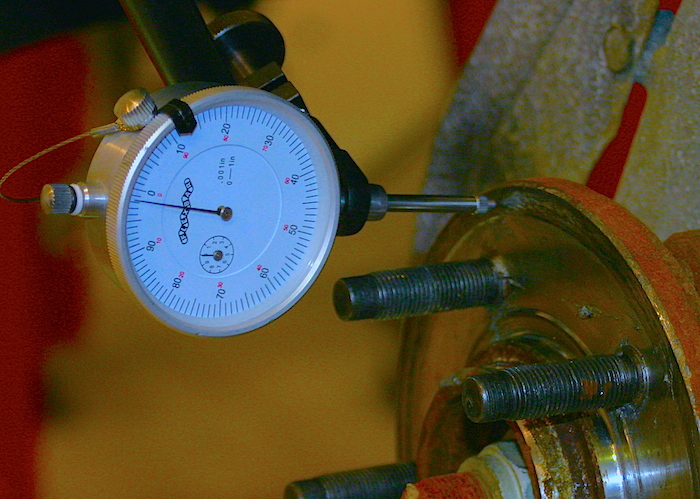

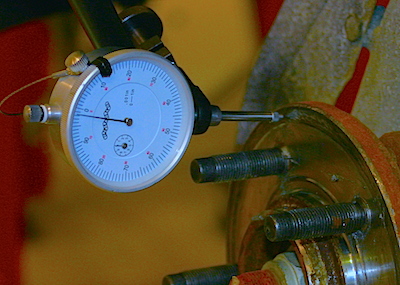

Runout

The hub flange is ground zero for pulsation problems. Always measure runout in the flange after installation. A distorted flange will have runout. This runout can cause vibration and eventually disc thickness variation in the brake rotors.

The hub flange is ground zero for pulsation problems. Always measure runout in the flange after installation. A distorted flange will have runout. This runout can cause vibration and eventually disc thickness variation in the brake rotors.

Every manufacturer has its own specification for wheel flange runout. Most specifications fall between 0.0015” and 0”. Most manufacturers are moving to a zero runout and endplay specification in the flange. This “perfect” specification is because any runout in the flange will be magnified by the rotor.

A flange can be damaged by curb strikes, installation errors or even corrosion. Extreme or catastrophic flange damage due to a curb strike is rare. But, some curb strikes can tweak the flange and cause runout. In most cases, the wheel and knuckle will deform before the flange or stub axle.

If a hub or bearing is over-torqued, it can damage the flange and cause runout. It can also damage the bearings and the axle shaft. This type of runout cannot be corrected by re-torquing the axle nut. The damage is permanent.

Pitting and corrosion where the rotor mates to the flange can induce runout. If the corrosion is too great, replace the flange or bearing. If a flange is distorted, there is also a good chance one of the wheel studs will break because the distortion will cause uneven clamping loads.

Wheelbearings are becoming less forgiving to installation errors. Changing race designs to improve fuel economy are more prone to failure if they are not installed with the correct procedures and tools. Using old methods and “feel” will cause comebacks and force you to work for free.